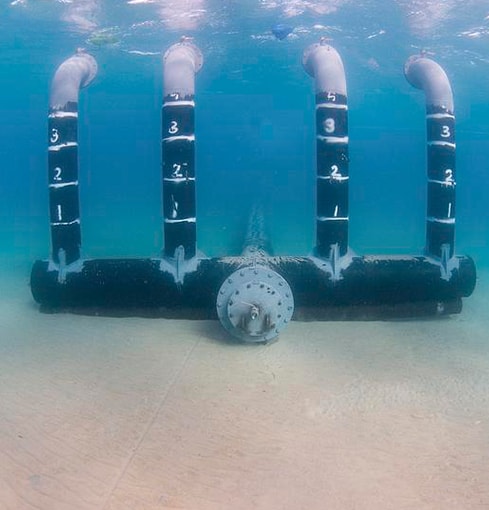

DI pipes are made from ductile iron, known for its high tensile strength, and are widely used for water supply and pressure sewerage applications. The V-Ducpipe ensures good health flows to every home since it is inherently corrosion resistant. It available in classes K7 and K9 with diameter DN 100 to DN 1200, conforming to IS 8329:2000 standards. This guarantees more pressure bearing ability, unmatched impact resistance and improves the capacity to sustain static or dynamic loading.

| Mechanical Property | Value |

|---|---|

| Tensile Strength | Min. 4,200 Kg/cm2 or 420 MPa |

| Yield Strength | 3,000 Kg/cm2 or 300 MPa |

| Minimum Elongation | 10% Up to DN 1000, 7% for diameter > DN 1000 |

| Modulus of Elasticity | 1.62 x 106 - 1.70 x 106 Kg/cm2 or 162,000 - 170,000 MPa |

| Hardness | Max. 230 BHN |

| Density | 7,050 Kg per cubic meter |

| Coefficient of Thermal Expansion | 11.5 x 10-6 per degree Celsius (°C) (for temperature range 20°C - 100°C) |

| Impact Strength | More than 80-150 joules |

| Standard Product | Ductile Iron Pipe suitable for Push-on-Jointing |

|---|---|

| Class of Pipe | C20, C25, C30, C40, C50, C64, Class K7,K9 |

| Size Range | DN 100mm to DN 1200mm |

| Standard Length (in meters) | 5.5 or 6.0 |

| Internal Linings | Cement Mortar Lining "Cement Type: Ordinary Portland Cement/Sulphate Resistant Cement/Blast Furnace Slag Cement/High aluminium cement" |

| Outside Coatings | Zinc Coating (130 gm/m2 or 200 gm/m2 or 400 gm/m2) with finishing layer of Bitumen/Blue Epoxy/Red Epoxy Alloy of Zinc and Aluminium with or without other metals having a minimum mass of 400 gm/m2 with finishing layer of Bitumen/Blue Epoxy/Red Epoxy |

| Outside Onsite Protection | Polyethylene Sleeving |

| Coating of Joint Area | Bitumen/Epoxy or as per customer requirement |

| Conforming Specifications | ISO 2531; BSEN 545; IS 8329 |

| SIZE DN | Thickness (mm) |

|||

|---|---|---|---|---|

| K7 |

K9 | |||

| Nom | Min | Nom | Min | |

| 100 | 5.0 | 3.7 | 6.0 | 4.7 |

| 150 | 5.0 | 3.7 | 6.0 | 4.7 |

| 200 | 5.0 | 3.7 | 6.3 | 4.8 |

| 250 | 5.3 | 4.0 | 6.8 | 5.3 |

| 300 | 5.6 | 4.3 | 7.2 | 5.6 |

| 350 | 6.0 | 4.7 | 7.7 | 6.1 |

| 400 | 6.3 | 4.8 | 8.1 | 6.4 |

| 450 | 6.6 | 4.9 | 8.6 | 6.9 |

| 500 | 7.0 | 5.2 | 9.0 | 7.2 |

| 600 | 7.7 | 5.8 | 9.9 | 8.0 |

| 700 | 9.0 | 7.0 | 10.8 | 8.8 |

| 800 | 10.4 | 8.3 | 11.7 | 9.6 |

| 900 | 11.2 | 9.0 | 12.6 | 10.4 |

| 1000 | 12.0 | 9.7 | 13.5 | 11.2 |

| 1100 | 14.4 | 12.0 | 14.4 | 12.0 |

| 1200 | 15.3 | 12.8 | 15.3 | 12.8 |